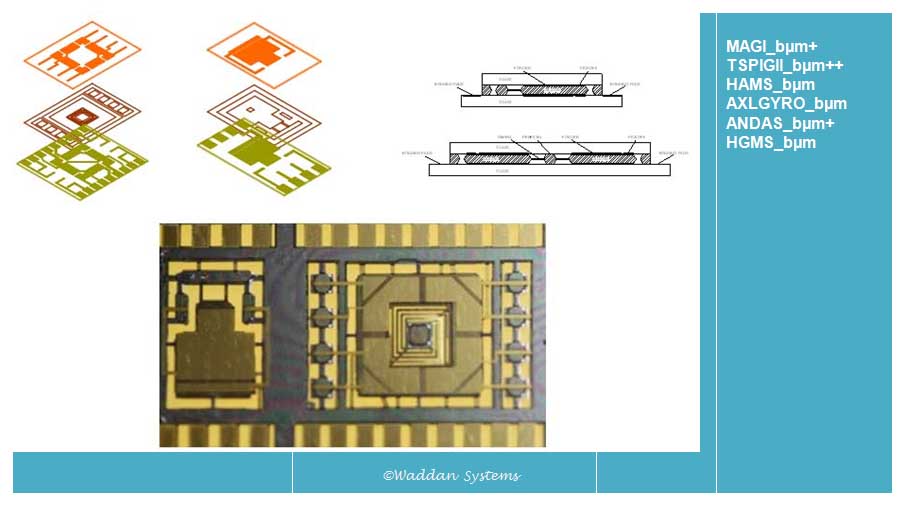

This type of sensors are made by etching off material from a substrate. The above picture shows Waddan's Axlgyro machined out of <100> silicon substrate, and is sandwiched between two Pyrex glass plates.

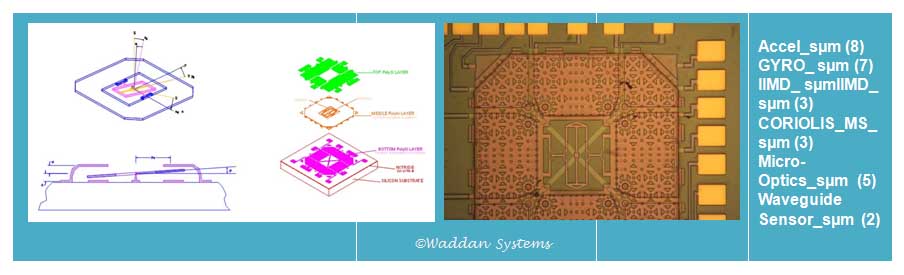

This type of sensors are made in three layers of thick polysilicon films. Surface micromachining produces these devices. The sensing element along with associated compliant structures is built in the middle layer, and the top and bottom layers make up the pick-off and forcer drive electrodes. The above picture shows a two-gimbal square gyro. The hole pattern is made to allow sacrificial etchant to reach under the top and middle layers for etching oxide.

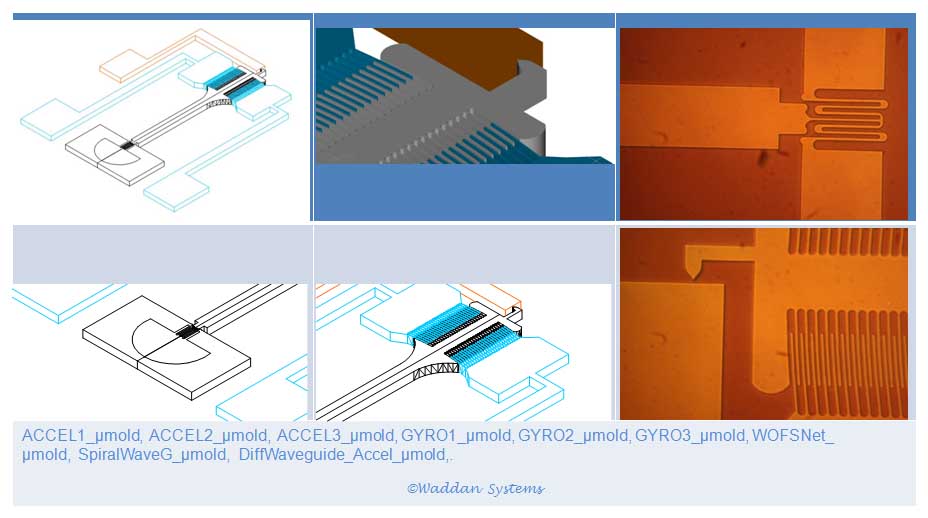

This type of sensors are made by depositing material

in micro cavities formed in photoresist or photoresist like materials and then dissolving away the

photoresist, and thereby leaving the deposited cast forms as the sensor elements. The above picture

shows two photographs of a micromolded pendulous accelerometer on the right. The top photo shows

the compliant hinge (made as a symmetric serpentine structure), and the bottom photo shows a section

of the forcer comb drive and the tip of the tunnel diode pick-off.

This type of sensors are made by depositing material

in micro cavities formed in photoresist or photoresist like materials and then dissolving away the

photoresist, and thereby leaving the deposited cast forms as the sensor elements. The above picture

shows two photographs of a micromolded pendulous accelerometer on the right. The top photo shows

the compliant hinge (made as a symmetric serpentine structure), and the bottom photo shows a section

of the forcer comb drive and the tip of the tunnel diode pick-off.

Laser

machining is used mostly for cutting to release sensing elements which

otherwise would break off during wafer processing. In its low power

form, the laser is also used to make positive ohmic contact (welding of

two metallic film surfaces bearing against each other). At microscopic

level, a laser cut line is not as smooth as that made by etching along

crystal planes. That's why it is difficult to form a complete micro

device using laser machining alone.

Laser

machining is used mostly for cutting to release sensing elements which

otherwise would break off during wafer processing. In its low power

form, the laser is also used to make positive ohmic contact (welding of

two metallic film surfaces bearing against each other). At microscopic

level, a laser cut line is not as smooth as that made by etching along

crystal planes. That's why it is difficult to form a complete micro

device using laser machining alone.