Just as a machinist uses machine tools like

lathe, borer, or shaper to

remove material from a block of metal to produce a desired part, a bulk

micromachinist does the same at micro level, only his tools involves

photo processing and chemical etching and some tricks of the .trade

routinely performed in semiconductor industry. A variety of materials

are employed for such micromachining, but silicon is predominantly used

because it is well understood, it is cheaper than other materials in

the processing category, and most importantly the equipment used in

semiconductor industry can be readily customized for this purpose.

Finally, when supporting electronics is necessary, it can be built

around the machined part. In addition to silicon, alumina, sapphire,

Pyrex, quartz, GaAs, Lithium Niobate, Lithium Tantalate etc. are also

employed for sensor manufacturing. With careful design and processing

plans practically any shape imagined

can be formed by bulk micromachining. Nevertheless, to date silicon has

the best processing time and cost advantage over the other materials.

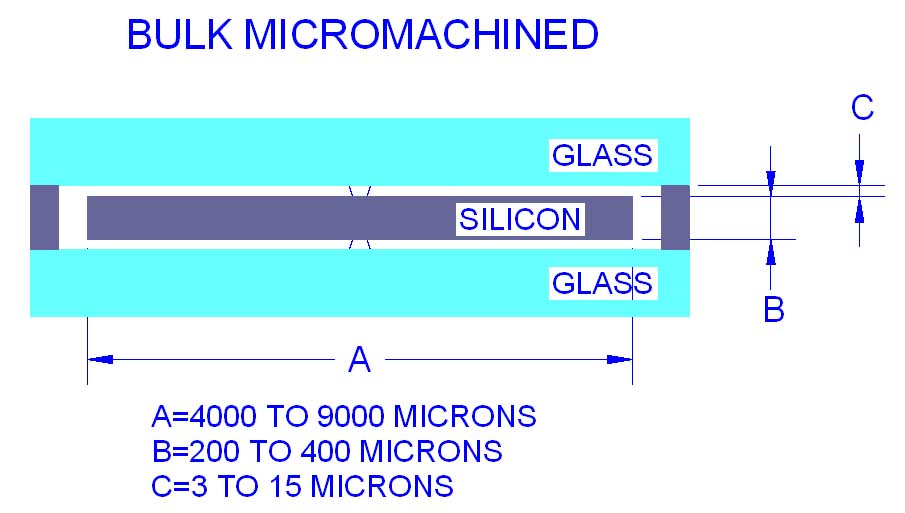

The bulk micromachined devices are usually encapsulated by glass or

some other substrate. Therefore, the devices generally have three

substrates. The typical thicknesses involved are shown in the figure.

Just as a machinist uses machine tools like

lathe, borer, or shaper to

remove material from a block of metal to produce a desired part, a bulk

micromachinist does the same at micro level, only his tools involves

photo processing and chemical etching and some tricks of the .trade

routinely performed in semiconductor industry. A variety of materials

are employed for such micromachining, but silicon is predominantly used

because it is well understood, it is cheaper than other materials in

the processing category, and most importantly the equipment used in

semiconductor industry can be readily customized for this purpose.

Finally, when supporting electronics is necessary, it can be built

around the machined part. In addition to silicon, alumina, sapphire,

Pyrex, quartz, GaAs, Lithium Niobate, Lithium Tantalate etc. are also

employed for sensor manufacturing. With careful design and processing

plans practically any shape imagined

can be formed by bulk micromachining. Nevertheless, to date silicon has

the best processing time and cost advantage over the other materials.

The bulk micromachined devices are usually encapsulated by glass or

some other substrate. Therefore, the devices generally have three

substrates. The typical thicknesses involved are shown in the figure.

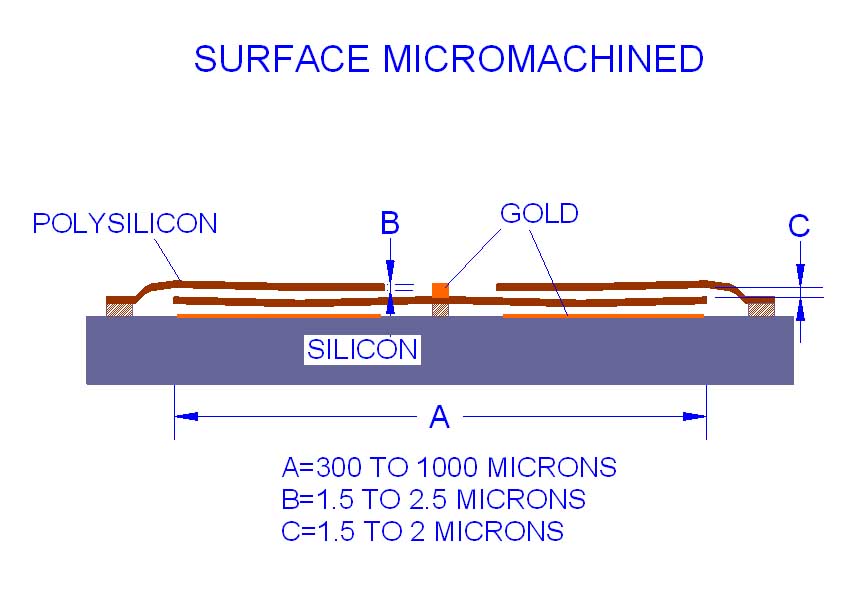

Surface micromachining is the fabrication of

micromechanical structures

by deposition and etching of thick structural and sacrificial films.

Thus, simple microstructures like beams or membranes as well as complex

structures like serpentine springs, gimbals, resonators, switches can

be fabricated on top of a silicon substrate. The main features of the

surface micromachining technology are the small microstructure

dimensions and the opportunity to integrate micromechanics and

microelectronics on the same chip. By use of VLSI compatible batch

processing, low cost microstructure fabrication can be achieved for

high volume applications. However, the thermal warping or distortion of

the sensing element and the flexures involved is a common problem as

the operating temperature varies. Operation at nominally fixed

temperature is necessary for predictable responses.

Surface micromachining is the fabrication of

micromechanical structures

by deposition and etching of thick structural and sacrificial films.

Thus, simple microstructures like beams or membranes as well as complex

structures like serpentine springs, gimbals, resonators, switches can

be fabricated on top of a silicon substrate. The main features of the

surface micromachining technology are the small microstructure

dimensions and the opportunity to integrate micromechanics and

microelectronics on the same chip. By use of VLSI compatible batch

processing, low cost microstructure fabrication can be achieved for

high volume applications. However, the thermal warping or distortion of

the sensing element and the flexures involved is a common problem as

the operating temperature varies. Operation at nominally fixed

temperature is necessary for predictable responses.

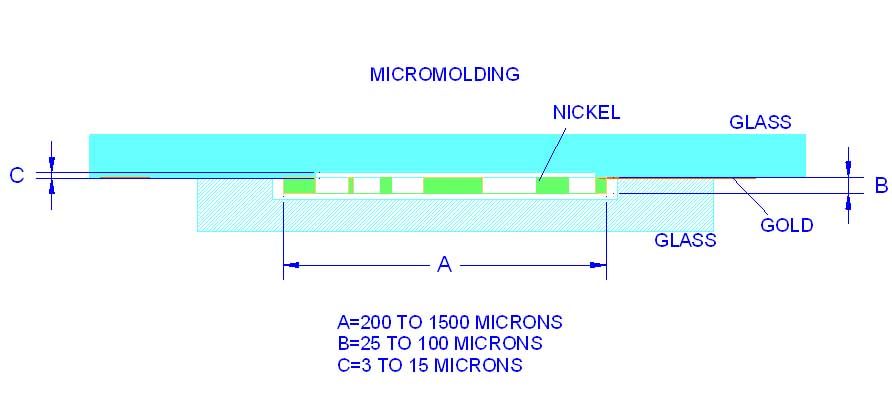

Micromolding is a process of making

electrodeposited castings in molds made in photosensitive sacrificial

materials like PMM resists using optical imaging. Generally, the casts

are 2D structure, but sometimes 3D structures are also made using a

multi-step micromolding technique. The deposition materials chosen are

usually nickel, gold or copper. The molding cavities are made on a

silicon substrate with a Ti film using photolithography. After

completing the deposition, the resist is dissolved leaving the sensing

element along with the surrounding support structures. To complete the

device fabrication, the micromolded elements are transfer bonded to a

Pyrex glass wafer, and the wafer used during deposition is removed by

removing the Ti film.

Micromolding is a process of making

electrodeposited castings in molds made in photosensitive sacrificial

materials like PMM resists using optical imaging. Generally, the casts

are 2D structure, but sometimes 3D structures are also made using a

multi-step micromolding technique. The deposition materials chosen are

usually nickel, gold or copper. The molding cavities are made on a

silicon substrate with a Ti film using photolithography. After

completing the deposition, the resist is dissolved leaving the sensing

element along with the surrounding support structures. To complete the

device fabrication, the micromolded elements are transfer bonded to a

Pyrex glass wafer, and the wafer used during deposition is removed by

removing the Ti film.

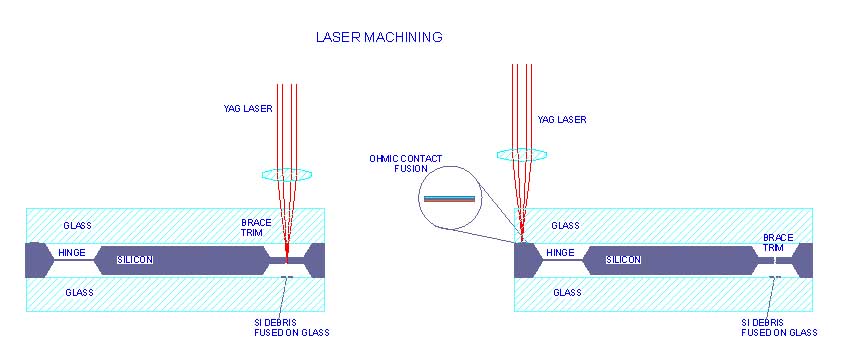

Laser machining is used

mostly for cutting to release sensing elements which otherwise would

break off during wafer processing. In its low power form, the laser is

also used to make positive ohmic contact (welding of two metallic film

surfaces bearing against each other). At microscopic level, a laser cut

line is not as smooth as that made by etching along crystal planes.

That's why it is difficult to form a complete micro device using laser

machining alone. It is mostly used as an assisting technology to trim

parts of structure that is difficult to form using standard methods.

Laser machining is used

mostly for cutting to release sensing elements which otherwise would

break off during wafer processing. In its low power form, the laser is

also used to make positive ohmic contact (welding of two metallic film

surfaces bearing against each other). At microscopic level, a laser cut

line is not as smooth as that made by etching along crystal planes.

That's why it is difficult to form a complete micro device using laser

machining alone. It is mostly used as an assisting technology to trim

parts of structure that is difficult to form using standard methods.