This is an in-house assembled wafer bonding equipment for bonding a Si wafer and a pyrex wafer. This is part of desktop equipment of a MEMS Research Lab. Air actuated (by a foot switch) heated electrodes are separated before pacing Si/Pyrex wafers, and then very high DC voltage is applied across them.

Anodic Bonding bonds a glass wafer with a silicon wafer, at times glass:silicon:glass bonding is also done where the glass serves as the packaging substrate. An electric field is used across the interface (~1000 VDC, 30 mA), while wafer stack temperature is raised to 250C under some pressure for uniform contact. When the current level comes down to 5 mA or so, the bonding becomes complete. To minimize thermal stresses in the wafers due to differences in coefficient of expansion, the wefer thicknesses have to properly calculated.

Power Requirement: 115 VAC, 50/60Hz

High Voltage Kepco Power Supply

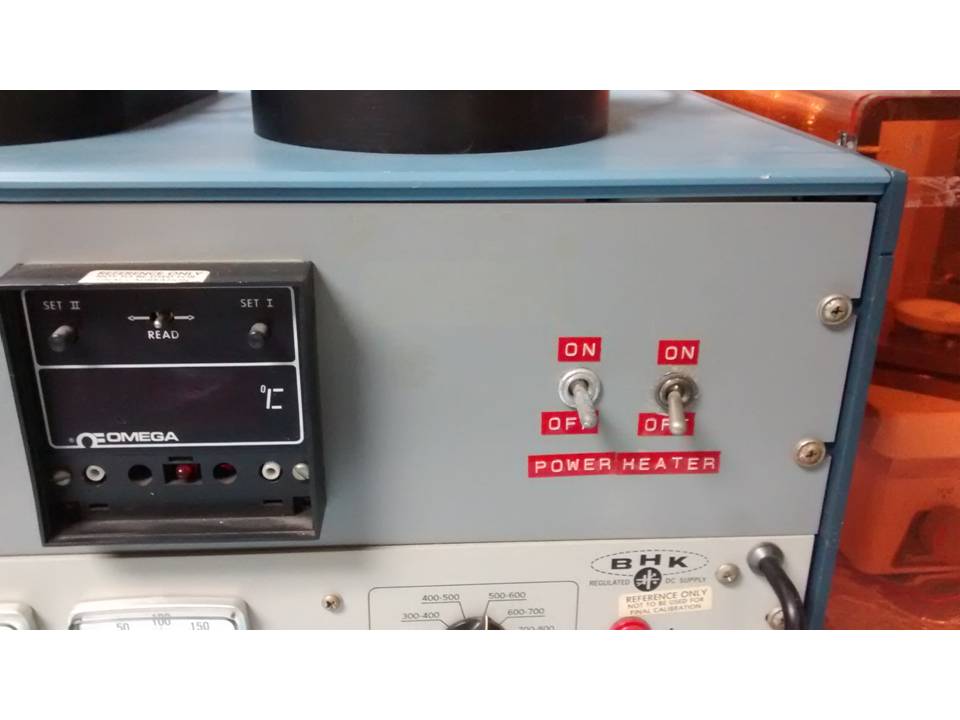

Electrode Heating Control

Current Monitor through the wafers

Heated Electrodes to Applying DC Voltage

Foot Switch for Electrode Separation/Closing Actions

Perfect for a startup or university with technical skills to take some technical responsibility

and save money over buying new.

It is available for inspection by appointments

Pricing negotiable. Make Offers.