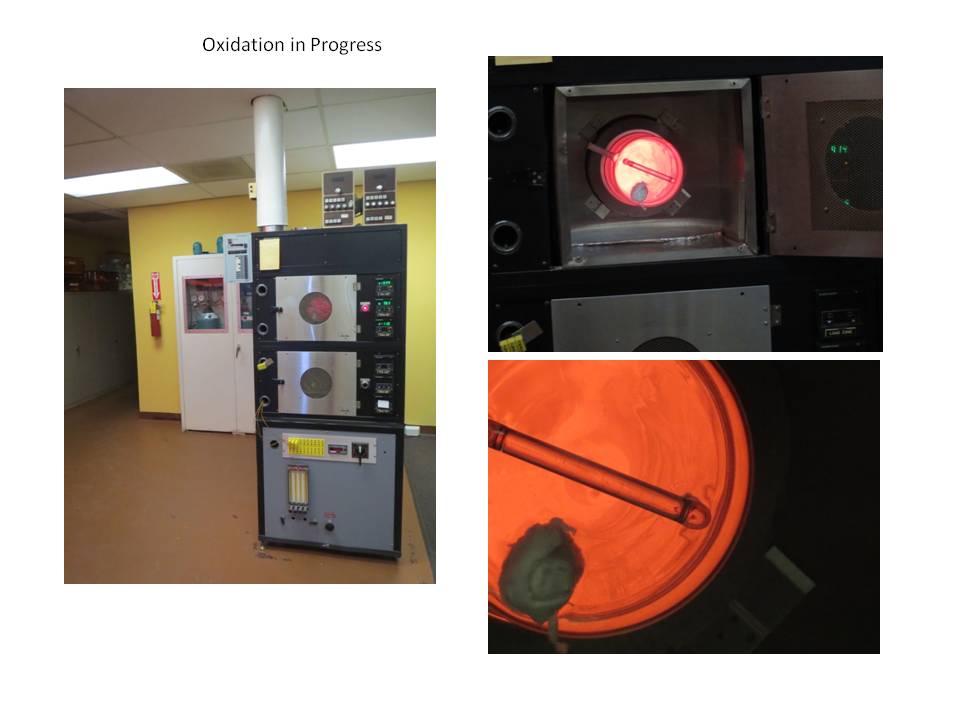

Well maintained Fully Operating Semiconductor Oxidation and Diffusion/Annealing Furnace

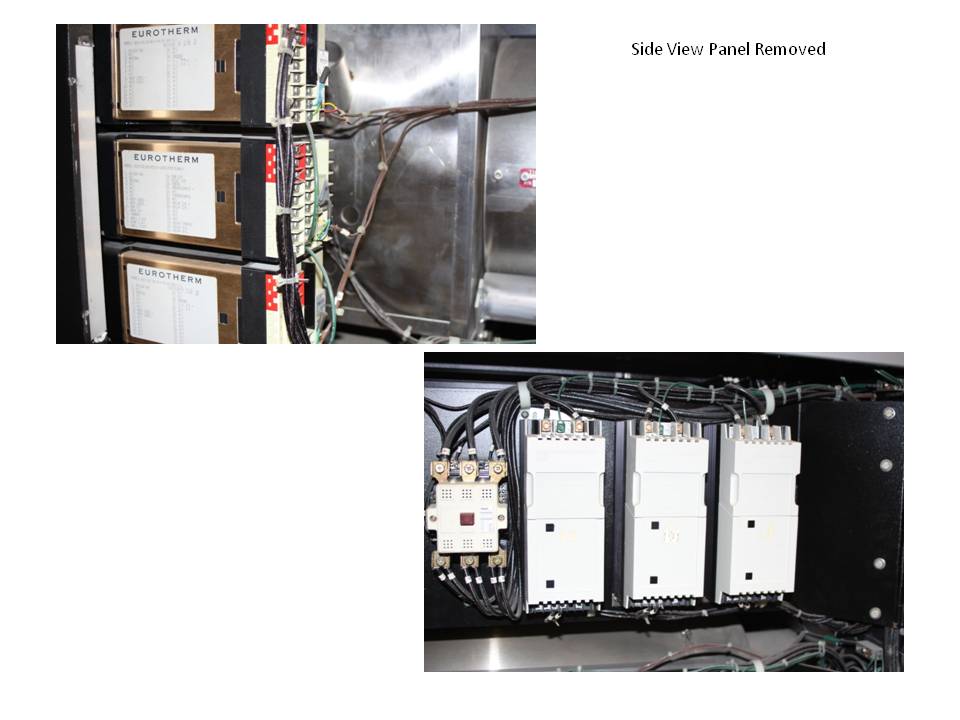

3 phase 220 VAC, 60 A Max

Max Temp 1200°C Black Max elements

2 X 130mm Quartz Tubes with End Caps

Source end of the Oxidation tube mates with a triple wall injector

3 zone temp control (Load/Center/Source)

Furnace is ideal for R&D and small lot production (up to 200 X 4” wafers). Optional flow-tubes and thermocouples are included for

manually controlling feed gases for experimental work.

Perfect for a startup or university with technical skills to take some technical responsibility

and save money over buying new.

Top tube for dry oxidation with triple wall gas injector (O2/H2/ThermoCouple)

Bottom tube for diffusion with (N2/O2) feed

(Both tubes are 5” in diameter)

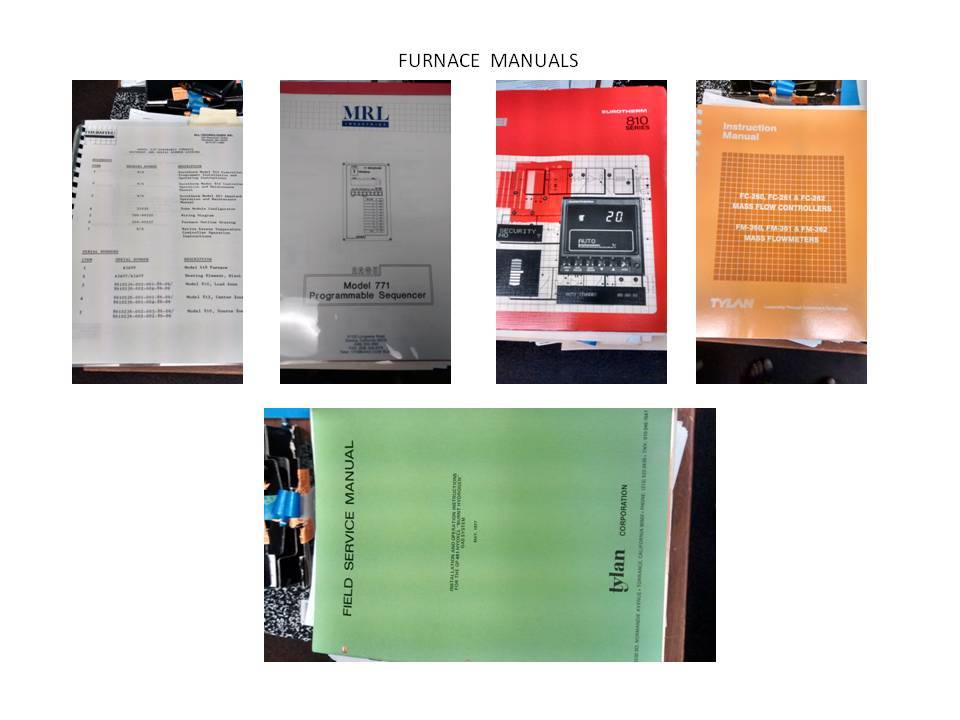

6 Eurotherm Model 810 Controllers

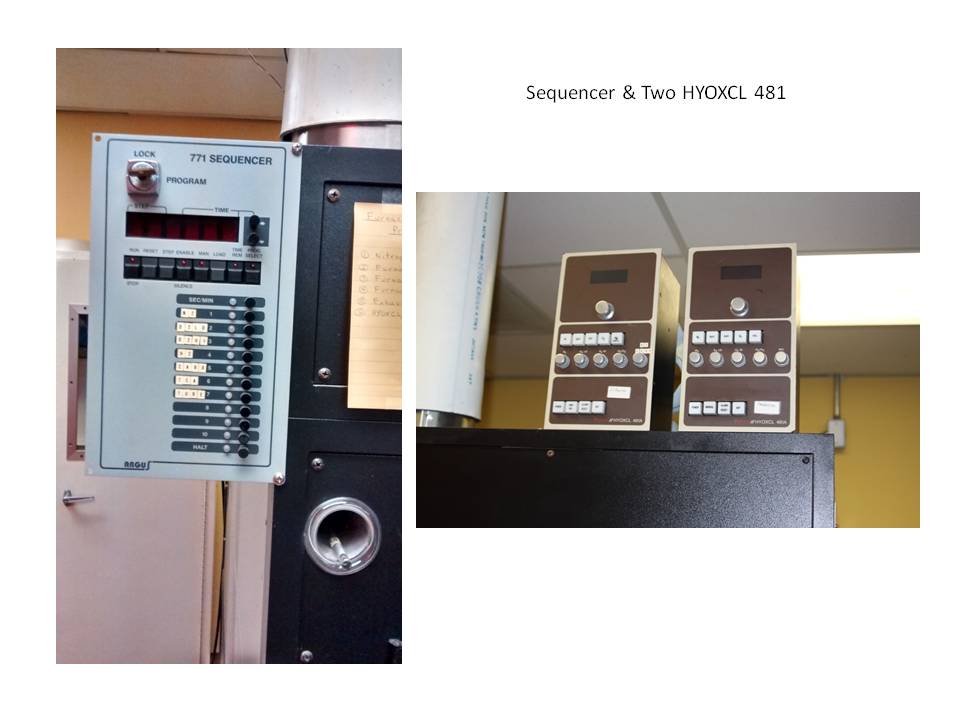

1 ARGUS Model 771 Sequencer timer (programmable with long life battery back-up)

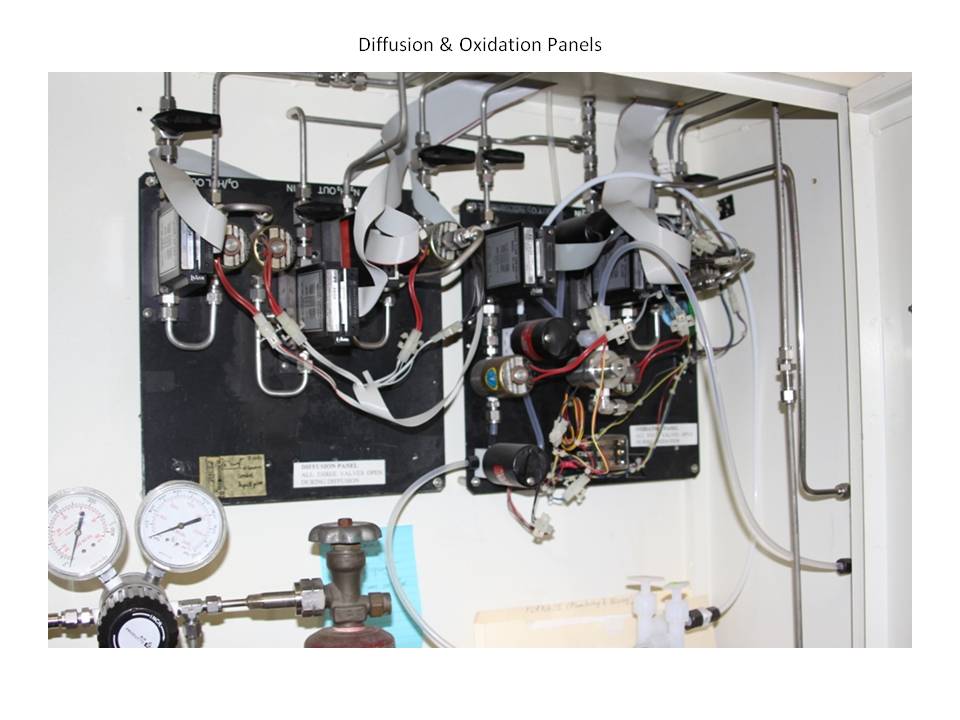

2 HYOXCL 481A

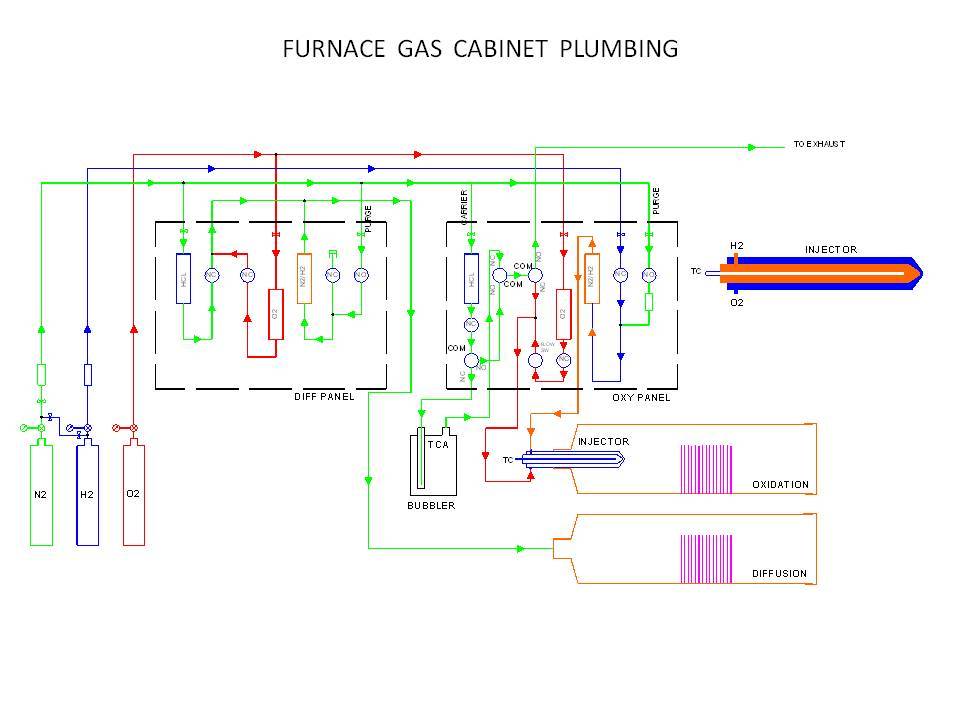

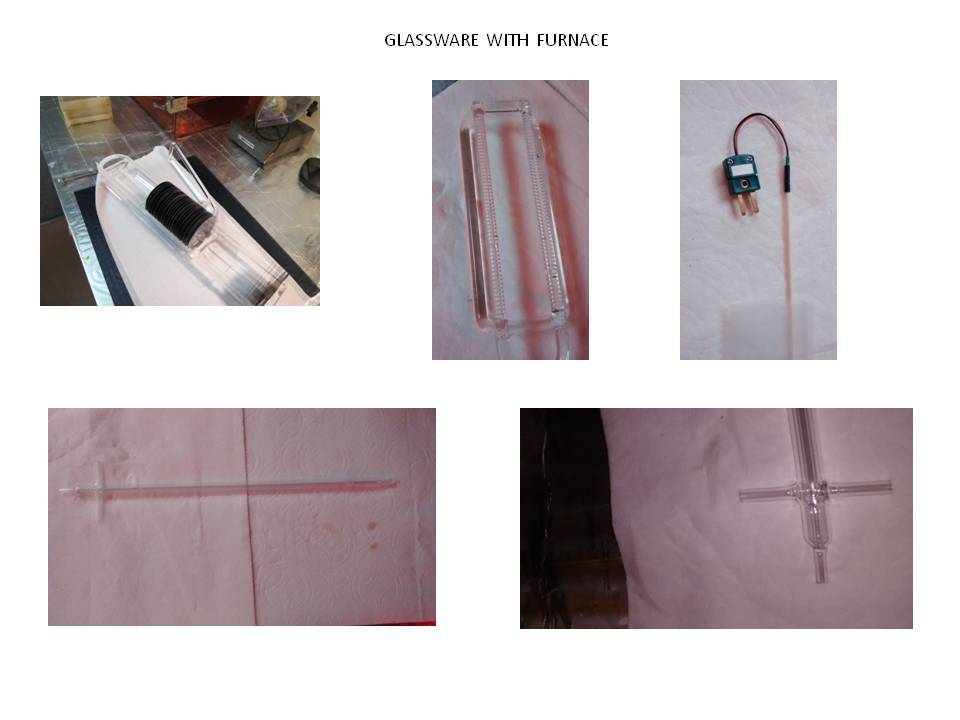

Triple wall custom designed injector for oxidation

Cross-Slotted Rail Boat for 200 wafers;

Pull Rods of various lengths;

Boat holder for loading/unloading of wafers from furnace tubes;)

Triple Thermocouple Bundle for temp calibration;

Furnace Center Zone (18” long) flat within 1°C.

Furnace Temp Max: 1200 °C.

3 Stainless Steel Regulators (O2, H2, N2),

2 Gas Control Boards with three Model FC-260F Tylan Mass Flow Controllers,

(on each board the three FC-260’s are calibrated for HCL, O2, H2/N2)

1 TCA (Trichloroethane Bubbler)

(TCA Bubbler shipping container is specially designed to meet the federal

transportation requirements. It is included in the sale price)

(All gas bottles shown in the pictures are EXCLUDED from sale

as they are rented from AIRGAS and will be returned to AIRGAS.)

The furnace is fully operational.

Two Brand New Quartz Glass Tube (Back-up for Oxy and Diff Tubes),

ASAHI Techno Glass with source-end modified for oxidation and diffusion in this furnace;

HDPE Tub for automatic Acid Washing of Furnace Quartz Glass Tubes;

two spare injectors; and

two thermocouples for injectors.

It is available for inspection by appointments

Pricing negotiable. Make Offers.