Well maintained Fully Operating Semiconductor Reactor for Slicon Nitride and Silicon Oxide Deposition at low temperatures

3 phase 220 VAC, 40 A Max

Height 41" X Depth 28" X Width 81"

Weight 970 lb

| PVD 1000 Process Data | Silicon Nitride | Silicon Oxide |

| Thickness Uniformity Across Substrate | < +/-8% | < +/-5% |

| Thickness Repeatability | < +/-5% | < +/-3% |

| Deposition Rate (150C, 1 Torr) | 60 Ang/min | 120 Ang/min |

| Cycle Time (1500Ang.) | 55 min | 45 min |

| Substrate Temperature | 50 - 250C | 50 - 250C |

| Reactor Pressure | 0.3 - 0.5 Torr | 0.3 - 1 Torr |

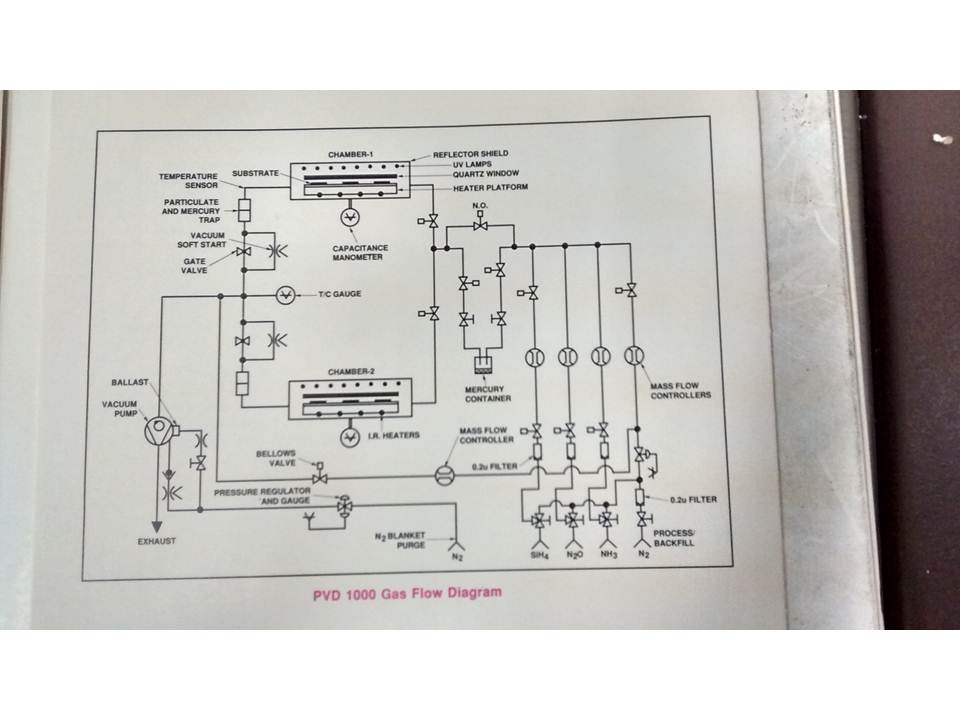

Reactant Gases

Fittings: 1/4" Metal Face Seals (VCR)

SiH4 20 sccm / 15 psi

NH3 200 sccm / 20 psi

N2O 200 sccm / 20 psi

The Tystar PVD 1000 Photo-Enhanced CVD Reactor uses UV light as an energy source for activating process gases for the deposition of

dielectric films at low temperatures (<150C). Films of silicon dioxide (SiO2), silicon nitride (Si3N4), silicon oxy-nitride (SiON)

and others can be deposited. Minimal stress is observed in these films due to the low deposition temperature. Since the UV photon

energy used does not ionize the process gases, no radiation damage from charged particles has been observed.

(Advantage: Unlike PECVD, PVD-1000 eliminates the need to introduce electrodes into the reaction chamber. The absence of electrodes

prevents ion damage to sensitive devices. Unlike LPCVD operating at high temperatures, PVD-1000 minimizes thermally induced stress

in the films, while providing excellent step coverage.)

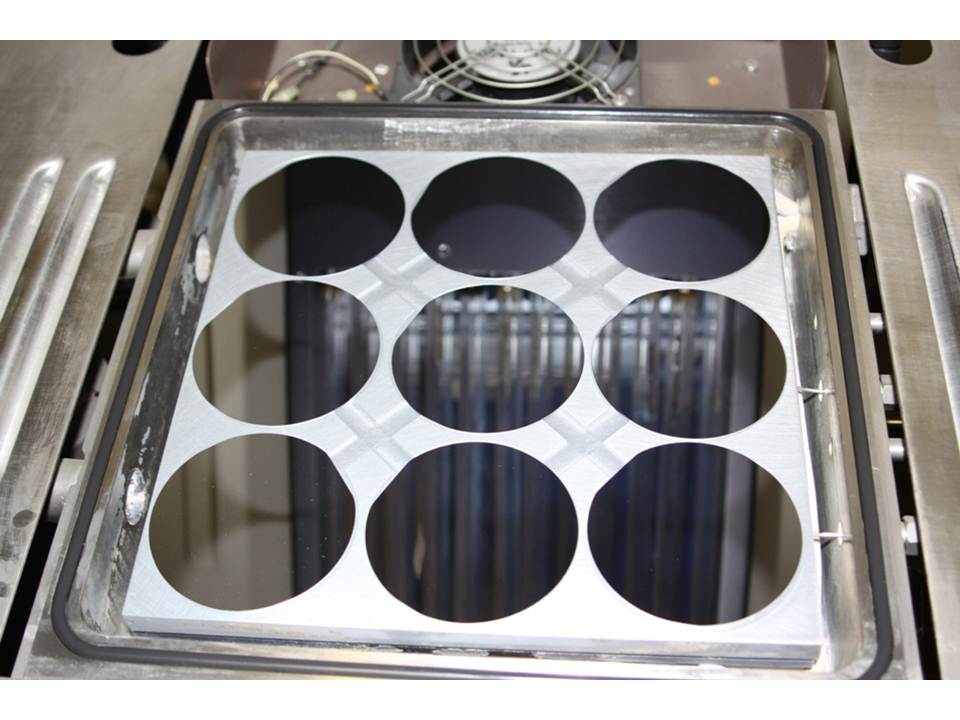

The PVD 1000 deposited films offer excellent step coverage. Our system has dual-process chambers - each can handle 9X3" wafers

(The base plate can be machined for larger or smaller size wafers; e.g. 5X4" or 4X5" wafers). The PVD 1000 reactor is used in a

variety of applications for film deposition on "III/V" materials, such as gallium arsenide, indium antimonide and other materials

that cannot tolerate higher deposition temperatures.

Reactor is ideal for R&D and small lot production (up to 18 X 3” wafers).

Perfect for a startup or university with technical skills to take some technical responsibility

and save money over buying new one.

2 Quartz Windows 12"X12", 1" thick,

2 Seals for Quartz Windows.

It is available for inspection by appointments

Pricing negotiable. Make Offers.